So here’s an interesting design.

The V1 case is 3D printed.. and it takes a whole day to print – assuming things don’t go wrong. It’s a good simple platform, and does the job. Not too expensive.

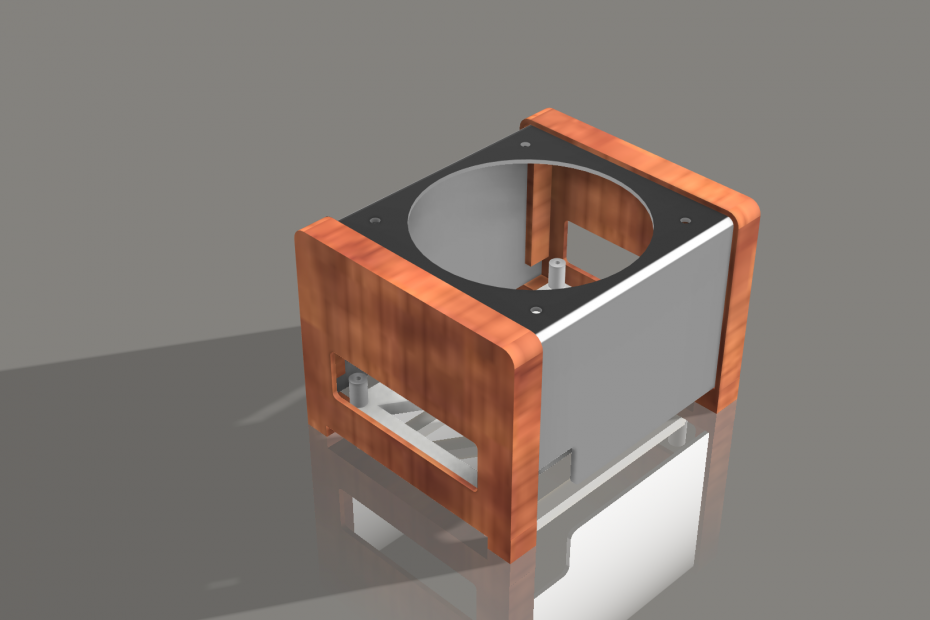

Well what happens if I use all my tools ?

Taking my cue from a toaster.. the sides are 12mm plywood or hardwood, or acrylic (or 6061 Aluminium ???). The main body is 1.6mm stainless steel that has been plasma cut. And holding it all together using the same holes as the DE10-nano PCB is a 3D printed ABS crossbrace that is strong and lightweight.

Will have a look at how workable the CNC toolpath is ! I’ve got to cut a 1.6mm wide slot through the wood to hold the steel.

And I have to bend the sheet metal.. hmmm…

Price ? Would be a bit more than a 3D printed case.. but might look a alot nicer, and I could make a lot of them quite quickly.